Trench shoring

Quick Shore Serie 260

max installation depth

Trench width:

sturt clearance height

mobile excavator:

Price

ALUMINIUM SHORING Series 250

The light construction makes the assembly quick and the installation with the "place and adjust" method is rather simple. The 60 cm high supports can easily be handled by two persons and the 2,40 m high aluminium trench boxes can be installed and removed with a mini excavator without any problems.The weight of a complete trench shoring unit with a length of 2.00 m is not more than 380 kg.

To fulfil the requirements of the aluminium shoring, specially pressed profiles have been developed to ensure the best material performance during extreme working procedures.

Light Weight Shoring Series 100

max installation depth

Trench width:

sturt clearance height

mobile excavator:

Price

3 m

0,66-2,23 m

0,94 m

9-13 t

Per Projekt

Light Weight Shoring Series 100 is suited for small to middle sized trench constructions and for the use of light construction machinery. Steel Light Weight Shoring offers a wide range of applications. It is best suited for supply lines, house connections and cable laying.

Slide Rail Shoring

the Slide Rail Shoring consists of individual trench shoring components which only inside the trench are combined to form a close shoring wall.

Plates, slide rails and rolling struts are slidable parallel to each other.

The trench width remains unchanged at any time during the construction phase. Due to this fact, the forces required for the installation and removal are considerably reduced. There is fewer vibration and the trench shoring itself is nearly settling-free.

The H-shape of the rolling strut offers perfect conditions in all work phases. During the phase of installation, the rolling strut is located in the lower range of the slide rail and thus gives the excavator operator a clear view and enables him to work with a short boom.

Available models

SINGLE SLIDE RAIL SERIES 790

This system offers a slide rail with one guide for the shoring plates. Trench depths of max. 3.80 m can be realized.

DOUBLE SLIDE RAIL SERIES 750

This system offers a slide rail with two guides for the shoring plates. Due to the second guide, not the entire shoring height but only the plate in one single guide has to be removed first.

TRIPPLE SLIDE RAIL SERIES 740

This system offers three guides for the shoring plates. The shoring is very robust and designed for extreme site conditions. Nevertheless, the system remains fast and flexible during the assembly.

Pile Chamber Series 400

Pile chambers are the first choice where supply lines are crossing.

This trench shoring system combines trench shoring plates and trench sheets. The pile chamber is the guiding frame for trench sheets and at the same time it is the upper support.

The excavator can easily push in the trench sheets before excavation takes place. The adjustment of the required working width is effected by means of SBH trench shoring spindles and extension pipes.

Pressbox Series 800

Crossing supply lines, building next to building, narrow access and close traffic – these are typical problems for trench shoring projects inside the city. On top, there is the necessity for noise control and for vibration-free installation of profiles. Another aspect of inner-city trench construction is the challenge to perform a work free of settling and the aspect of compacting.We has solved all these problems with its Pressbox: A trench shoring system which perfectly combines the fulfilment of technical requirements and cost-effectiveness.Even bad soil conditions, as for example gritty or non-cohesive grounds, do no longer make any problem when using the SBH Pressbox. With this trench shoring system, you can realize a completely shored

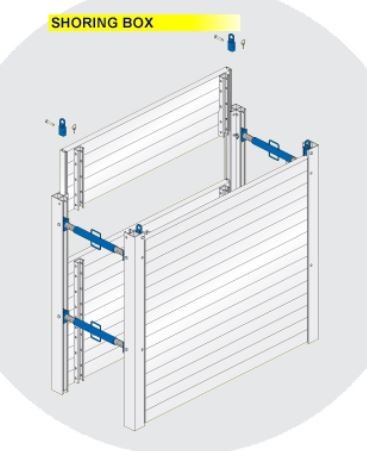

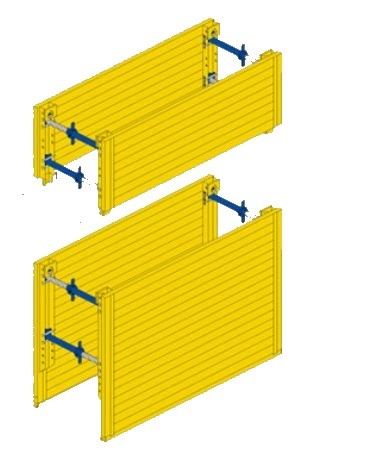

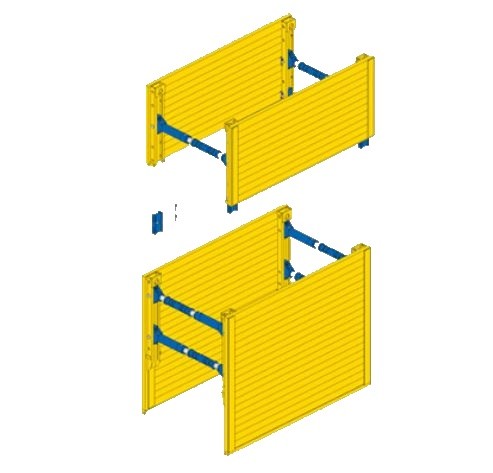

Box Shoring

Trench Shoring boxes are particularly used where the ground is not stable. With their spring mounted flexible spindles, the trench shoring boxes can be installed with the "cut and and lower" method. The range differs with regard to the thickness of plates and the safe working loads.

Light Box Series 300

Our Light Box combines a light plate construction with a flexible spindle. This makes this type of trench shoring so perfect for small to medium trench shoring projects and for the use of light construction machinery. This trench shoring is also suitable when the ground is not stable. The flexible spindle makes it suitable for the installation with the "cut and lower" method.

The light box is mostly used for supply lines, house connections and cable laying.

The robust construction of the side profiles allows higher strut clearances compared to the light weight trench shoring and the spindle we use with this type of trench shoring allows greater trench widths.

EXTRA BOX Series 500

The SBH Extra Box is the economical solution between the SBH Light Box and the SBH Standard Box.

The stronger trench shoring plate construction allows higher loads compared to the Light Box. With the same earth pressure the deformation in the trench shoring is

reduced considerably.

With the flexible spindle, the SBH Extra Box can be installed where the ground is not stable and using the "cut and lower" method. The use of a reinforced post profile makes the trench shoring box very strong and it meets any specific requirements.

STANDARD BOX Series 600

In order to minimize deformations the side profiles have been equipped with additional bars. The flexible spindle allows the installation in non-stable grounds with the "cut and lower" method.

The Standard Box is suited especially for supply lines in depths of 2.00 – 4.00 m. The safe working loads exceed the presumSTANDARD BOX WITH TRANSFORMATION PROFILE Series 600

Another advantage is that the box can be transported dismantled and can be assembled on site so that no special transport is required.

ROLLING STRUT BOX Series 780

The Rolling Strut Box is a trench shoring box which at the same time offers the advantages of the slide rail shoring. The trench shoring plates are strut and

supported by the well-proven rolling strut successfully used in the slide rail trench shoring for a long time.

The strut clearance heights are infinitely variable and can be set according to the specific needs of the site. The required working width is realized by means of

distance pieces. Each component is individually slidable during installation and removal. Plates and rolling struts are moved parallel to each other.

This reduces the forces required during the installation and removal significantly. When laying excessively long pipes, the rolling struts can be positioned offset

in height and thus allowing the laying of the pipes.

Rolling Strut Boxes are mainly used for trench shoring projects where also great strut clearance heights are required.

MANHOLE BOX Series 600

The Manhole Box is always used when wider manholes have to be installed within a working trench.

The trench shoring plate body is designed as a U-form and the wings have a thickness of 0,40 m. Thus, a 0,80 m wide manhole is formed.

Ahead and behind the manhole, normal trench shoring boxes ensure the trench safety. The spindles and accessories are identical to those of the trench shoring boxes.

Maxi Box Series 630

The Maxi Box allows the laying of pipes with a very great pipe diameter. It is possible to positon three different strut clearance heights. The max. strut clearance height is 2,29

m.

The top of the trench shoring plate is extremely reinforced in order to stand the high loads during the lowering. At the same time, the robust cutting edge allows to cut even firm ground.

In order to minimize the deformation, the side parts are equipped with additional bars. The use of the flexible yellow trench shoring spindle allows to resist high compressive forces. Maxi Boxes are mainly used in trench depths of 2 – 4 m.

Drag Box Series 650

The Maxi Box allows the laying of pipes with a very great pipe diameter. It is possible to positon three different strut clearance heights. The max. strut clearance height is 2,29

m.

The top of the trench shoring plate is extremely reinforced in order to stand the high loads during the lowering. At the same time, the robust cutting edge allows to cut even firm ground.

In order to minimize the deformation, the side parts are equipped with additional bars. The use of the flexible yellow trench shoring spindle allows to resist high compressive forces. Maxi Boxes are mainly used in trench depths of 2 – 4 m.